Water type mold temperature machine

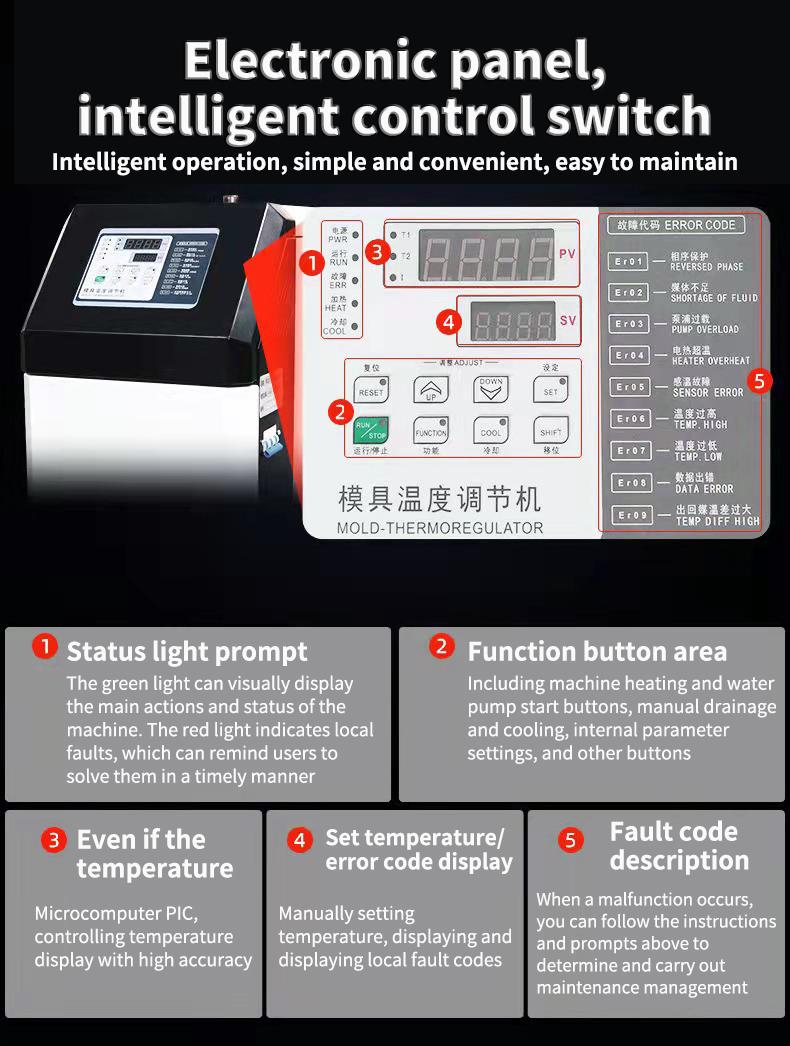

Application&Features

1. Using oil or water as the heat medium, safe and reliable

2. Two sets of heating tubes provide an automatic warning system when the oil cylinder is overloaded, and the circuit is automatically cut off to ensure safety

3. Stainless steel container is used, which is corrosion-resistant and has a long service life

4. Adopting computer precise temperature control and independent cooler to make the temperature more stable

Oil type mold temperature machine

Application&Features

1. Using oil or water as the heat medium, safe and reliable

2. Two sets of heating tubes, automatic warning system for oil cylinder overload, automatic circuit cut-off to ensure safety

3. Stainless steel container is used, which is corrosion-resistant and has a long service life

4. Adopting computer precise temperature control and independent cooler to make the temperature more stable

Mold temperature machines are generally divided into water temperature machines, oil temperature machines, and two-stage machines. The temperature control accuracy can reach+0.1 ℃, and they are widely used in various industries such as plastic molding and die-casting, rubber tires, rollers, chemical reaction vessels, bonding, and mixing.

Working principle of mold temperature machine:

The mold temperature machine pipeline is connected to the mold oil passage to form a circuit, and the heat transfer oil circulates under the action of the pump. The temperature sensor transmits data to the control system, automatically adjusts the heating/cooling action, and controls the temperature of the heat transfer oil.

The principle of heating up the mold temperature machine: When heating up, the temperature control meter automatically analyzes the data from the temperature sensor and controls the status of the heater to achieve the set temperature. The principle of cooling down the mold temperature machine: When cooling down, the heater stops heating, the temperature control meter controls the status of the cooling solenoid valve, and the cooling water enters the heat exchanger to cool down the heat transfer oil