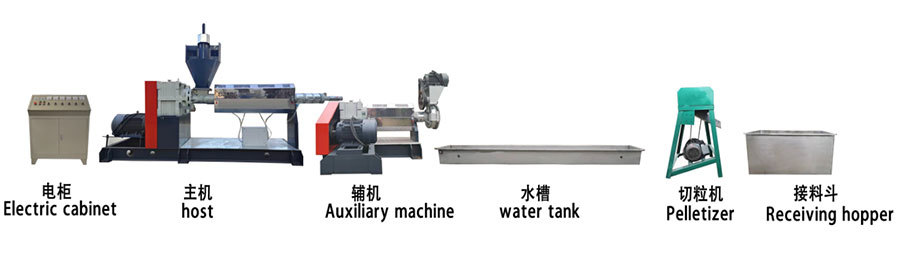

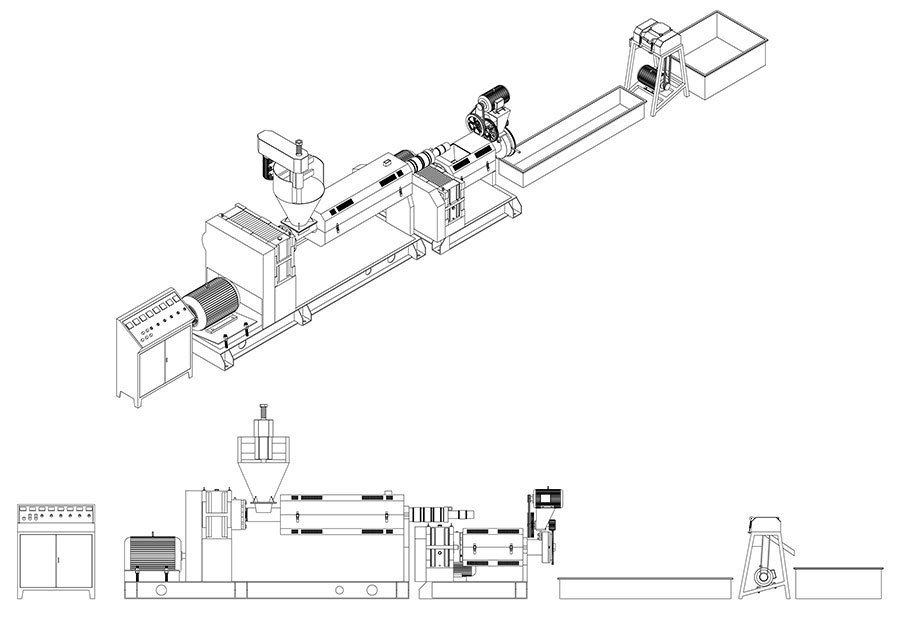

PN2-125/125S Double-stage membrane material water-strand

Plastic Granulator - Function:

1.Adopting special screw design and different configurations, it is suitable for the regeneration and color mixing granulation of various plastics such as PP, PE, PS, ABS, PA, PVC, PC, POM, EVA, LCP, PET, PMMA, etc.

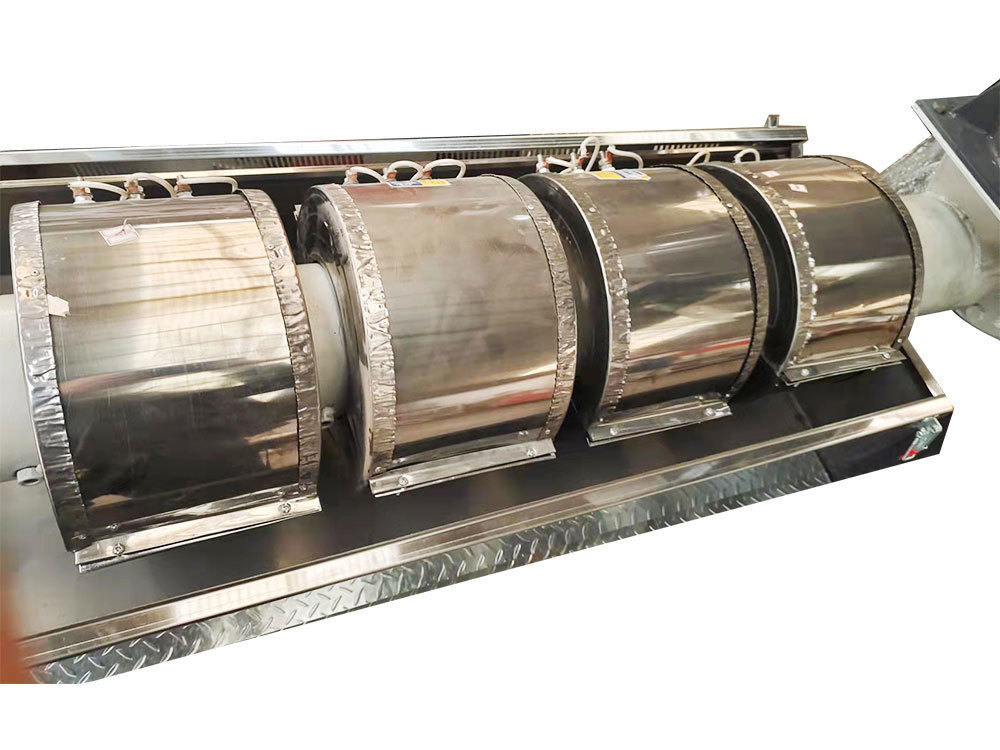

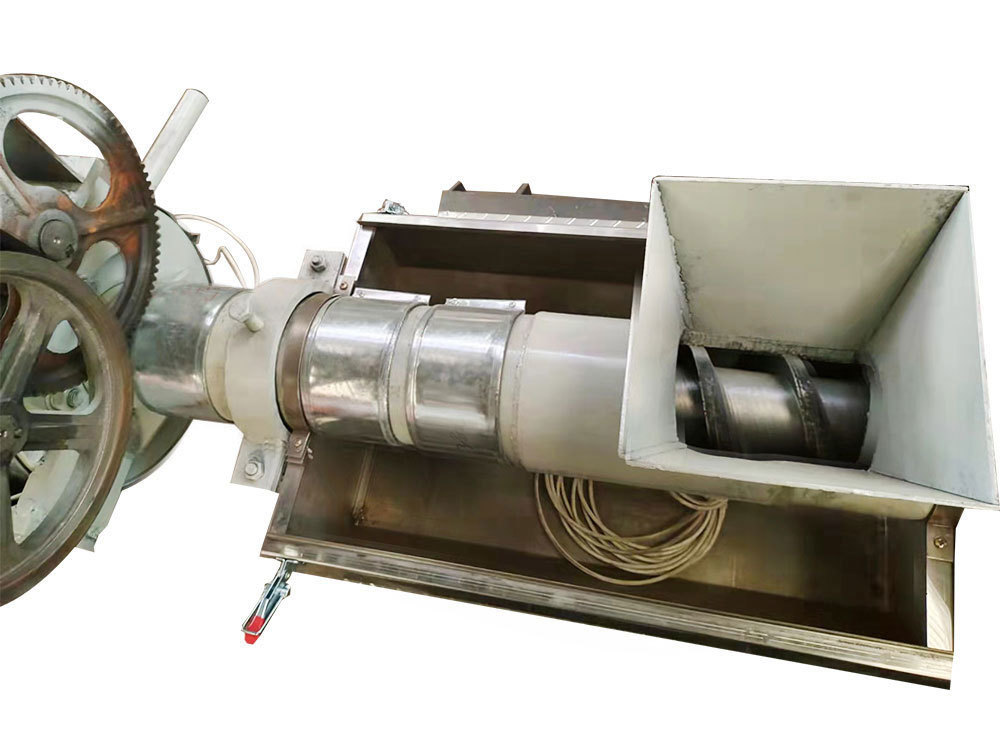

2.The gearbox adopts a high torque design, achieving noise free and smooth operation. The screw and barrel have undergone special hardening treatment, which has the characteristics of wear resistance, good mixing performance, and high yield.

3.The design of vacuum exhaust or ordinary exhaust port can remove moisture and exhaust gas during the production process, making the material more stable and the rubber particles more solid, ensuring excellent product quality.

Plastic Granulator - Production Principle:

Using high-temperature melting, plasticization, and extrusion processes to change the physical properties of plastics, achieving plasticization and molding of plastics.

Plastic Granulator - Purpose:

Plastic granulators are mainly used for processing waste plastic films (industrial packaging films, agricultural films, greenhouse films, beer bags, handbags, etc.), woven bags, agricultural convenience bags, pots, barrels, beverage bottles, furniture, daily necessities, etc. They are suitable for most common waste plastics and are the most widely used and popular plastic recycling processing machinery in the waste plastic recycling industry.