The main features of knife grinder machine include:

1. Short grinding time, small grinding amount, and high grinding accuracy: The grinding machine can complete the grinding task in a short time with a small grinding amount, ensuring high-precision grinding effect and making the blade sharp.

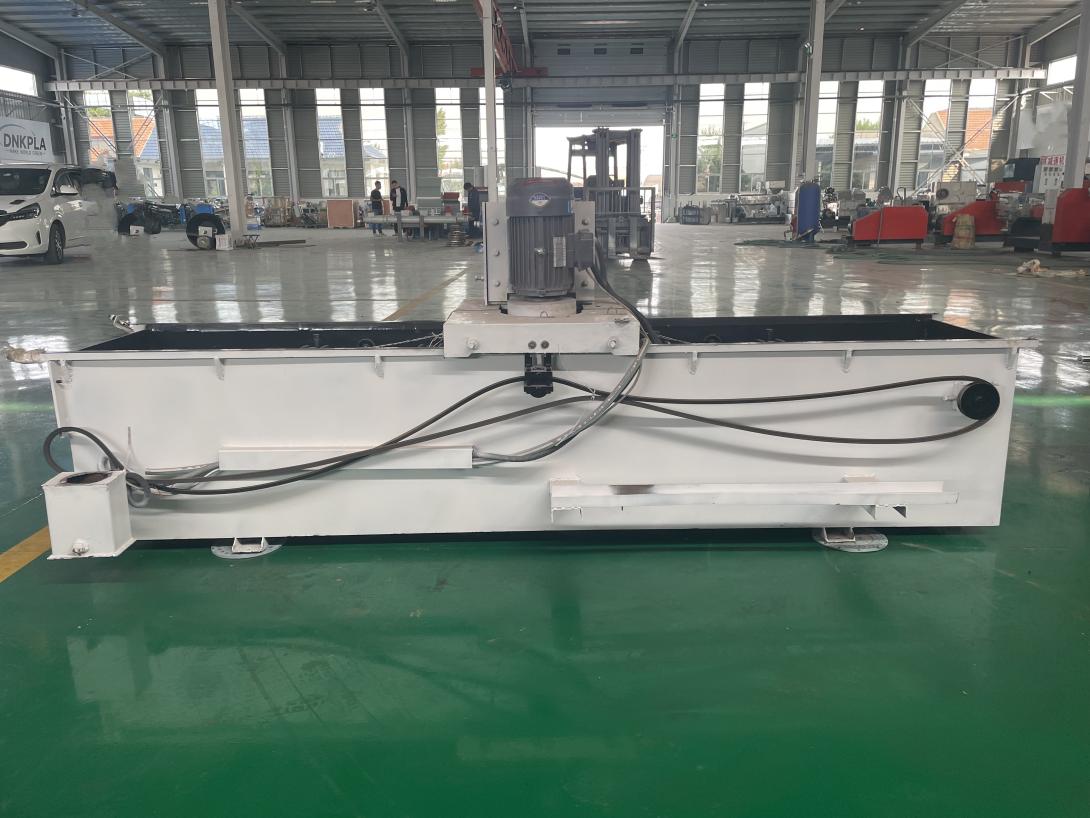

2. Structural improvement: The design of the grinding machine adopts a steel plate closed welding structure, which improves the strength of the machine body and extends its service life. The transmission part has been changed from belt transmission to rack transmission, ensuring reliability and stability

3. Protection function: Some high-end sharpening machines are equipped with motor protection functions, including overload protection, locked rotor protection, undervoltage protection, overvoltage protection, leakage protection, etc., to ensure the service life of the motor

4. Safety design: Fully enclosed large transparent inspection window, with a safety switch on the top cover, automatically cutting off the power when opening the cover, improving the safety of operation

5. High precision: Using high-precision bearings imported from Switzerland, reducing vibration, ensuring precise blade grinding, minimal loss, and maintaining blade roundness. Rolling style fine adjustment rotating feed shaft, achieving high-precision fine adjustment feed

6. Environmentally friendly design: The fully enclosed structure, combined with dust exhaust vents and dust collection tanks, effectively collects dust and maintains a clean and refreshing environment.

Fixed travel speed of grinding head

1. Manual feed of grinding wheel

2. Gear and rack transmission

3. Cantilever fuselage structure

4. Mechanical knife holder table

5. Knife holder rotation: manual transmission

6. Workbench rotation angle: 0 to ± 90 degrees