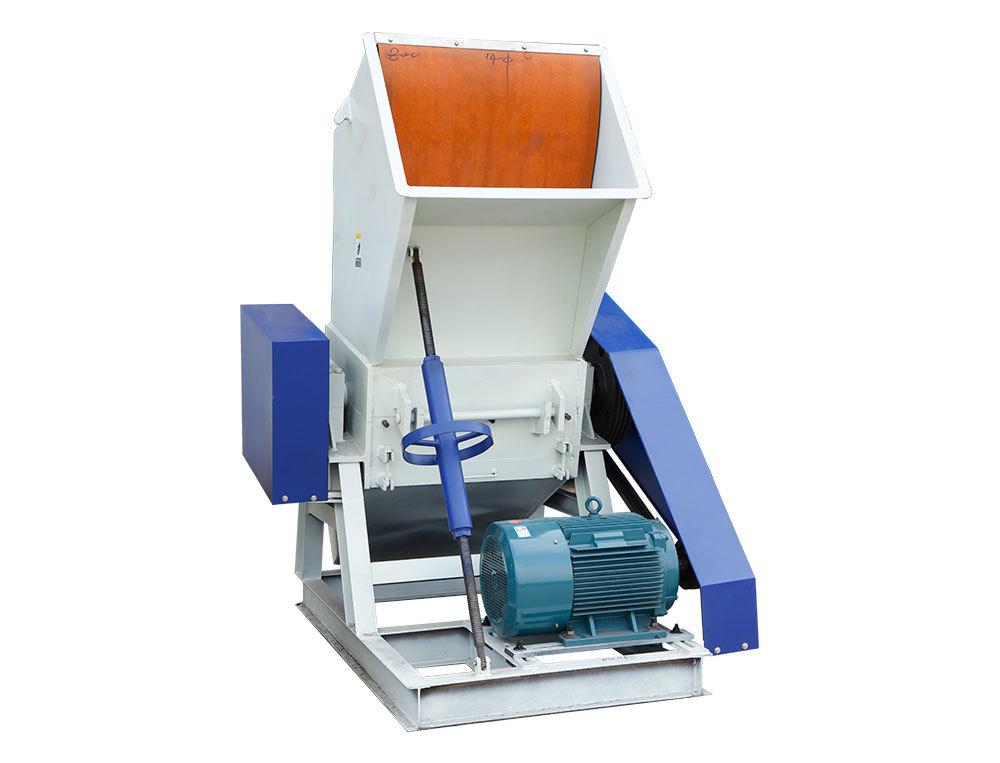

Product features:

1. Low noise crushing, double-layer thick steel plate sound insulation, scientific curved box design

2. Double layered barrier, widened and enlarged feed inlet, rapid material dropping, and vigorous feeding

3. High strength claw knife mode, making powder easier to use

4. Standard brand 55 silicon blades, with SKD-11, D2 and other materials to choose from

5. The brand motors are Yexiang and Dongxu

6. It can crush cow bones, medicinal herbs, plastic films, rubber materials, sheet materials, and spout materials

7. The mesh aperture can be customized in size

8. Equipped with an emergency stop switch for safer operation

9. Replace the rubber wood hand twist for easier disassembly

10. Glass style locking nut, convenient for daily operation

11. High strength universal wheel, stable operation without shaking

The characteristics of the crusher include:

1. Strong adaptability: It can handle materials of various hardness and humidity, and is not easily clogged.

2. Compact structure: Small in size and light in weight, suitable for small production lines with limited space.

3. Easy to adjust: The crushing gap can be adjusted as needed to control the discharge particle size.

4. Low energy consumption: Increase production by more than 30% under the same energy consumption.

5. High fineness: The finished product has high fineness, adjustable particle size distribution, and strict control over large particles.

6. Wide application: Used in fields such as waste treatment, raw material preparation, energy production, medicine, and food processing.

There are three main categories:

(1) Hard plastic crusher, suitable for crushing various small and medium-sized plastic sheets:

1. Crushing and recycling of ABS, PE, PP and other sheet materials;

2. A rectangular feeding port uniquely designed for crushing board materials, which facilitates the feeding and crushing of long strip boards and improves work efficiency. Optional suction fans and storage buckets can be used to form a board crushing and recycling system, which can fully utilize the recycling efficiency;

3. Using sealed bearings to ensure that the bearings rotate well for a long time; Reasonable blade design, uniform granulation of products; The knife holder undergoes heat shrink treatment, resulting in a beautiful and elegant appearance design;

(2) Powerful plastic crusher:

1. The blade structure is between a claw blade and a flat blade, suitable for crushing plastic products such as ordinary sheets, pipes, profiles, plates, and packaging materials;

2. Universal plastic crusher, using sealed bearings to maintain good bearing rotation for a long time;

3. The blade design is reasonable, using alloy steel blades, the product is uniformly granulated, the blade seat is heat shrunk, and it has undergone strict balance testing. The external design is beautiful and generous;

(3) Plastic pipe and plastic crusher:

1. Suitable for crushing and recycling various small and medium-sized plastic pipes, such as PE, PVC pipes, silicon core pipes, etc;

2. The uniquely designed round tube feeding port for crushing pipe materials facilitates the feeding and crushing of long and narrow pipe materials, improving work efficiency. The optional combination of suction fan and storage bucket to form a pipe crushing and recycling system can fully utilize the recycling efficiency;

3. Using sealed bearings to maintain good bearing rotation for a long time; Reasonable blade design can make the product evenly granular; The heat shrink treatment of the blade holder makes the appearance design beautiful and generous.